|

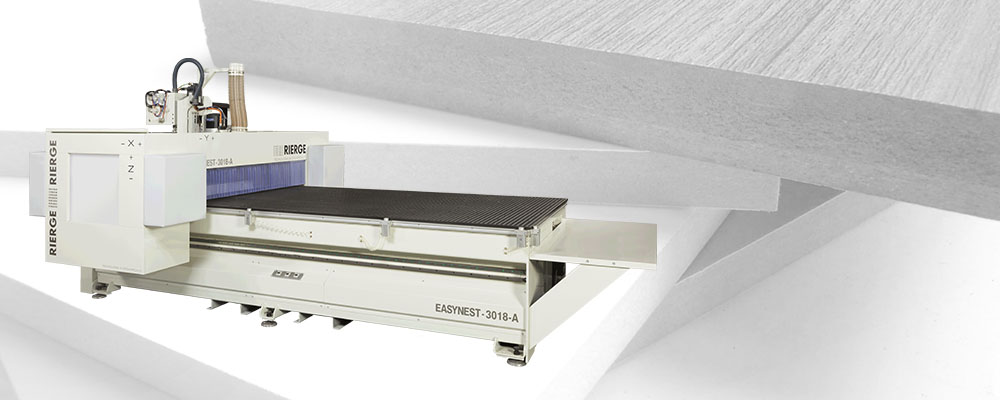

PHENOLIC MULTIFUNCTIONAL TABLE

The table is planned and slotted in square sections, operations performed by the machine itself, which guarantees perfect perpendicularity, square and alignment of the three axes.

The working surface is grooved in 22×22 mm and 30 mm squares between centers. The material used for the table is MAX COMPACT 85FH of 20mm thickness. In this table different vacuum sockets are available, from which we must choose the ones we need depending on the pieces to be machined.

For the delimitation of the work area, we will place a rubber in the channels, to hold the piece by a vacuum.

In case we need to elevate the machining piece, we have a wide variety of aluminum suction cups and reference stops along the table perimeter that allows to place the board accurately.

In Nesting system a “martyr· board is placed to protect the resine table and, by its porosity, we subject the other piece placed over this martyr.

Our machines, due to the Rierge’s exclusive system, can even hold more than one piece and thus be able to mechanize two boards simultaneously.

In the machine bench vacuum meters are available to display the level of vacuum.

In case of wanting to raise the piece of the multifunctional table, we have a wide variety of suction cups and presses.

|